Engraving is the most durable and legible way of marking information. It involves removing a layer of surface material in order to permanently mark or indent numbers, text, or images, typically on metal, plastic, or glass surface. Engraving can be carried out to precise specifications on a whole host of different materials.

We 4 Maintenance Technical Services LLC Engraving uses a combination of traditional and the most technologically advanced processes available today, from long-established hand engraving and the use of manual pantographs to modern CNC Rotary Engraving, the use of milling and routing machines, CNC CO2, Fibre and Galvo laser engravers, sublimation, ink printing, chemical etching, and digital print.

Bespoke engraving solutions are our specialty. We can engrave materials designed to withstand high impacts and wet or highly corrosive environments and we can create precise cutouts or profile shapes in a wide range of sizes, thicknesses,es and finishes with a host of engraved color options.

The most commonly used plastics for engraving are phenolic and impact acrylic laminates of different colored layers which reveal a different colour layer beneath when the top layer is engraved away, allowing for clearly readable markings. These laminates can be rigid or flexible and suitable for both indoor and outdoor use.

We4m is one of the Efficient Residential & Commercial Plumbing services which is trusted by more than 650,000 people. We are just a call away. 058 4394 7644, 058 1102663

Laser cutting/profiling

Lasers are used for many purposes. They are used is for cutting metals and plastic plates. The laser cutting process is highly accurate, yields excellent cut quality, has a very small cutting width and small heat affect zone this makes it possible to cut very intricate shapes and small holes.

Rotary Engraving

Rotary engraving is the process of using a rotating cutter in a motor powered spindle to cut into material in order to create engraved grooves which form raised characters or graphics. We often fill the engraved areas with a coloured paint to provide a contrast to the metal, we can use rotary engraving to leave raised letters or images for a “cast” look or to create Braille print.

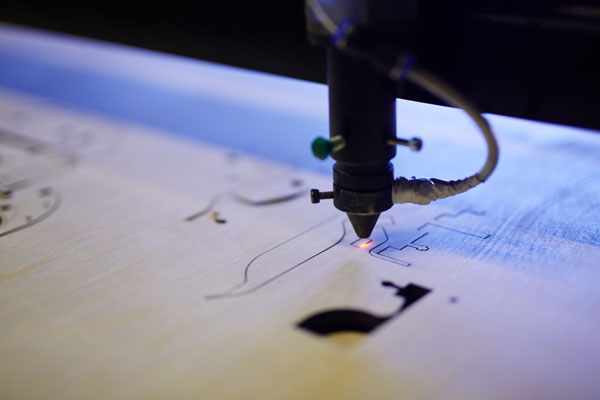

Laser Engraving / Cutting

Laser engraving is the process of using lasers to engrave an object or material. We use Co2/Fibre/Galvo CNC laser engraving for both engraving and for cutting holes or shapes as it achieves much finer marking and cutting than CNC milling. Lasers can engrave metals, wood, rubber, glass and plastics (including Perspex) as well as natural materials such as slate, marble and granite.

How Laser cutting/profiling works?

The laser beam is a column of very high-intensity light, that is focused onto the plate. The focused laser beam goes through the bore of a nozzle right before it hits the plate. The beam has to be precisely focused so that the shape of the focus spot and the density of the energy in that spot is perfectly round consistent and centered in the nozzle. The high power density results in rapid heating, melting, and partial or complete vaporizing of the material. On a CNC laser cutter, the laser cutting head is moved over the plate in the shape of the desired part, thus cutting the part out of the plate.

How Rotary Engraving works?

CNC rotary engraving systems use a computer controlled rotating cutting tool in a motorised spindle to remove surface material. The rotating cutting tool, or cutter, cuts into the material surface to a predetermined depth in order to produce a groove of the same shape and size as the tool. The rate of the cutter rotation is known as the cutting speed and the lateral movement is the feed rate. Both the cutting speed and the feed rate have a profound effect on the quality of the finished cut. In general, softer material may have higher cutting speeds and feed rates and can be engraved in a single pass. Harder materials require lower cutting speeds and feed rates may need to be engraved in two passes. The first pass will remove most of the material and the second pass will create a clean cut.

Rotary engraving can be used on a wide variety of materials including acrylics, soft plastics, rigid plastics (phenolic), soft metals (brass and aluminium) and harder metals (steel and stainless steel).

How Laser Engraving/Cutting works?

A laser will either vaporize the material at which it is pointed or it will change the material surface to create a contrast, depending on the type of laser used. By managing the output power of the laser, its pulse rate, and the speed the laser moves over the surface, the cutting or engraving effect can be precisely controlled for each specific material and by reducing the power to a minimum, very thin materials can be engraved or cut.

In instances where the laser cannot remove the surface of a particular material, a chemical layer is initially sprayed onto the material surface which fixes on to the material when the laser is applied. The excess spray is then rinsed off to leave a permanent black image on the surface.